Is Pex Pipe Better Than Copper For A Whole House Repipe In Us?

Choosing the right piping material for a whole house repipe is a major decision for American homeowners. This choice affects water quality, durability, home value, and long-term maintenance costs. Across the United States, many homes are reaching the age where repiping becomes necessary. Older houses often still use galvanized steel or aging copper lines. Leaks, corrosion, and low water pressure push homeowners to consider full replacement. At that point, the most common question is whether PEX or copper is the better option. Both materials are widely used in US residential plumbing. Both meet national plumbing code standards when installed correctly. However, they perform very differently in real-world conditions. Climate, water chemistry, labor costs, and home layout all play a role. Homeowners want a solution that lasts without constant repairs. They also want to control costs during a major renovation. Plumbers often have strong opinions based on experience. Online advice can be confusing or contradictory. This makes it hard to know which option is truly better. The answer depends on practical factors, not marketing claims. This guide breaks down those factors clearly and honestly. It focuses on US homes, codes, and plumbing conditions. You will learn the strengths and limitations of both materials. By the end, you will be able to make a confident, informed choice.

Is Pex Pipe Better Than Copper For A Whole House Repipe In Us?

This question compares PEX plastic piping and traditional copper piping for full home repiping. The goal is to choose the best material for durability, cost, and performance. Both options are legal and widely used across the United States. Understanding the differences helps homeowners protect their investment and plumbing system.

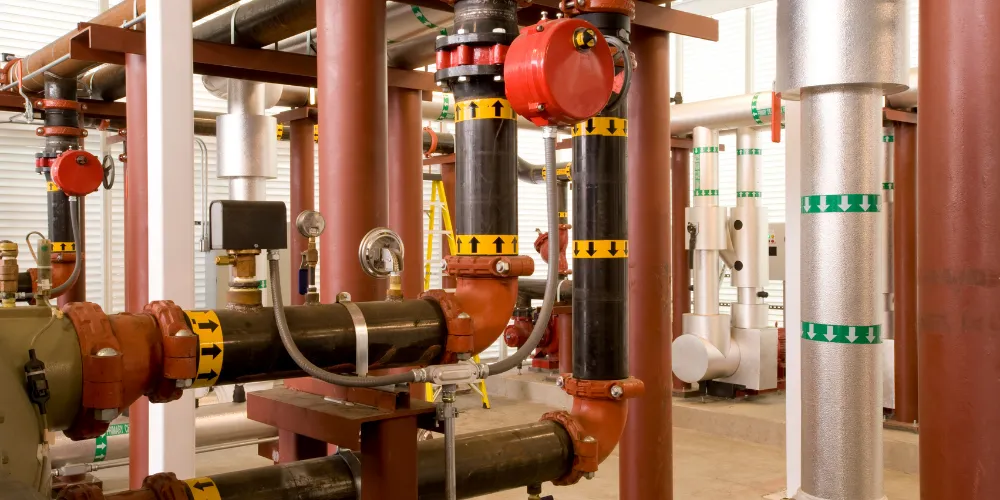

Understanding What a Whole House Repipe Involves

A whole house repipe replaces all existing water supply lines. This includes hot and cold water pipes throughout the home. In US homes, repiping is often needed after 40 to 70 years. Corrosion, pinhole leaks, and pressure loss are common triggers. Repiping is not a small repair. It affects walls, ceilings, and sometimes flooring. The choice of pipe impacts installation time. It also affects how invasive the work becomes. PEX allows flexible routing through walls. Copper requires rigid, straight runs. This difference changes labor intensity. Labor is a major cost factor in the US. Repipe projects are often completed in phases. Minimizing disruption is important for families. Material choice affects how long water must be shut off. It also affects future repair accessibility. Whole house repiping is a long-term investment. Most homeowners want a solution that lasts decades. Resale value is also a consideration. Buyers often ask about plumbing updates. Choosing a widely accepted material matters. Insurance companies may also review pipe types. Understanding the scope helps frame the decision. It prevents unrealistic expectations. Both materials can work well when installed properly. The key is matching the pipe to the home’s needs. This understanding sets the stage for comparison. It keeps the decision practical and informed. Skipping this step leads to regret later. A clear overview supports smarter planning.

Material Composition and How It Affects Performance

Copper is a natural metal with proven longevity. It has been used in US plumbing for decades. PEX is a flexible plastic made from cross-linked polyethylene. PEX is newer but widely adopted. Copper resists UV exposure naturally. PEX must be protected from sunlight. Copper handles high temperatures well. PEX also handles hot water but has limits. Copper is rigid and strong. PEX is flexible and forgiving. Flexibility allows PEX to absorb pressure changes. This reduces stress on joints. Copper relies on soldered or pressed joints. PEX uses fittings and expansion or crimp systems. Each system has different failure risks. Copper can corrode based on water chemistry. PEX is not affected by acidic water. In areas with aggressive water, copper can fail early. PEX remains stable in those conditions. Material composition directly affects lifespan. It also affects maintenance needs. Understanding how materials behave helps avoid surprises. Water quality varies across the US. Local conditions should guide the choice. Neither material is universally superior. Performance depends on environment and installation quality. Material properties influence long-term reliability. This is not just about preference. It is about compatibility with your home. Choosing wisely prevents premature failure.

Installation Time and Labor Costs in the United States

Labor costs vary widely across the US. In many regions, labor is the biggest repipe expense. PEX installs faster than copper in most homes. Its flexibility reduces cutting and fitting. Fewer connections mean fewer potential leak points. Copper installation is more time-consuming. It requires precise cutting and joining. Soldering takes skill and time. Fire safety precautions also slow the process. PEX can be installed with fewer wall openings. This reduces drywall repair costs. In multi-story homes, PEX routing is simpler. Copper often requires more demolition. Shorter installation time reduces disruption. Families can stay in the home during many PEX repipes. Copper repipes often require more downtime. Contractor availability also matters. Many US plumbers now specialize in PEX. Labor rates reflect this shift. PEX-friendly installations often cost less overall. Copper labor remains higher in most markets. Time savings translate directly into cost savings. This matters for budget-conscious homeowners. Installation speed does not mean lower quality. It means modern methods are more efficient. Choosing PEX can reduce project stress. Copper still has a place in certain homes. But labor considerations favor PEX for many projects. Understanding labor impact clarifies total cost. This helps avoid budget overruns.

Durability and Lifespan in Different US Climates

The United States has diverse climates. Plumbing materials respond differently to temperature extremes. Copper performs well in stable climates. However, it can burst when frozen. PEX is more freeze-resistant. It can expand slightly without cracking. This is valuable in colder regions. States like Minnesota and Colorado benefit from this. In hot climates, both materials perform well. PEX must be protected from UV exposure. Copper naturally resists sunlight damage. Homes with exposed piping favor copper. PEX lifespan is estimated at 40 to 50 years. Copper can last longer under ideal conditions. However, water quality affects copper more. Acidic water shortens copper life significantly. PEX is unaffected by water chemistry. This makes it reliable in many regions. Coastal areas often have corrosive water. PEX performs well in these locations. Durability depends on installation quality. Poor installation shortens lifespan for both. Climate should influence material choice. There is no one-size-fits-all answer. Understanding local conditions is critical. Homeowners should consult local professionals. Climate-aware decisions prevent failures. Durability means fewer repairs. Fewer repairs mean lower lifetime costs. This factor heavily influences long-term value.

Water Quality and Health Considerations

Water quality is a top concern for homeowners. Copper pipes can leach metals if corroded. This can affect taste and safety. PEX does not corrode. However, it may slightly affect water taste initially. This usually fades over time. PEX is certified for potable water use. US standards regulate its safety. Copper has a long safety history. Both materials meet health codes when approved. Local water chemistry matters greatly. Acidic water increases copper leaching risk. PEX avoids this issue entirely. Some homeowners prefer copper for perceived purity. Others prefer PEX for chemical stability. Neither option is unsafe when properly installed. Health concerns should be discussed with professionals. Testing water chemistry helps guide decisions. Municipal water reports provide useful data. Private well users should test regularly. Material choice can affect filtration needs. Copper may require corrosion control. PEX typically does not. Health considerations are often overemphasized online. Reality is more balanced. Both materials are widely accepted. Code compliance ensures safety. Choosing based on facts is important. Avoid fear-based decisions. Focus on proven performance.

Resistance to Corrosion, Scale, and Pinhole Leaks

Copper is vulnerable to corrosion. Water chemistry is the main factor. High acidity causes pinhole leaks. These leaks are common in older US homes. PEX does not corrode or scale. Mineral buildup does not adhere easily. This keeps internal diameter consistent. Copper can narrow over time. Reduced diameter lowers water pressure. PEX maintains flow efficiency longer. Scale buildup affects performance. PEX resists internal buildup better. In hard water areas, this matters. States with mineral-rich water see copper issues. PEX avoids these problems. Pinhole leaks are costly and disruptive. They often require repeated repairs. PEX eliminates this risk entirely. This reliability appeals to many homeowners. Copper still performs well in balanced water. Not all regions experience corrosion issues. Local history is a good indicator. Ask neighbors about plumbing problems. Patterns often emerge by area. Corrosion resistance influences long-term maintenance. Lower maintenance means lower costs. This is a strong argument for PEX. Copper requires closer monitoring. Material choice affects peace of mind. Reliability is a major deciding factor.

Noise Levels and Water Pressure Differences

Plumbing noise is a common complaint. Copper pipes transmit sound easily. Water hammer is more noticeable. PEX absorbs vibration and movement. This results in quieter operation. In multi-story homes, this is noticeable. Late-night water use is less disruptive. PEX reduces banging and rattling sounds. Water pressure is similar for both materials. However, PEX’s flexibility allows smoother routing. Fewer sharp turns improve flow. Copper requires elbows and joints. Each joint adds resistance. PEX home-run systems improve pressure balance. This is common in modern US installations. Each fixture gets a direct line. This reduces pressure drops. Copper systems often share branches. Simultaneous use affects pressure more. Noise reduction improves comfort. Pressure consistency improves usability. These factors affect daily life. Small differences matter over time. PEX offers advantages in modern layouts. Copper still performs well when designed properly. System design matters as much as material. Professional planning is essential. Noise concerns influence homeowner satisfaction. Quiet systems feel higher quality. PEX often wins in this category.

Code Compliance and Acceptance Across US States

Plumbing codes vary by state and city. PEX is approved in most US jurisdictions. Some areas adopted it later than others. Copper is universally accepted. Local codes may affect installation methods. Permit requirements apply to both materials. Licensed plumbers ensure compliance. DIY installations must meet code standards. PEX requires proper supports and protection. Copper requires approved joining methods. Inspections verify workmanship. Homeowners should check local regulations. Most states now support PEX fully. Municipal acceptance continues to grow. Insurance companies recognize both materials. Resale inspections typically accept PEX. Documentation matters for future buyers. Using approved materials avoids issues. Code compliance protects homeowners legally. It also ensures safety and performance. Unpermitted work can cause problems later. Always work with licensed professionals. This applies regardless of material choice. Code acceptance should not be a barrier. Both options are mainstream. Local knowledge is key. Professional guidance simplifies compliance. Avoid assumptions about legality. Check before starting any repipe. Proper approval ensures peace of mind.

Cost Comparison: Upfront and Long-Term Expenses

PEX is generally less expensive upfront. Material costs are lower than copper. Labor savings add to cost reduction. Copper prices fluctuate with market conditions. PEX prices are more stable. Total repipe cost varies by home size. In many US homes, PEX saves thousands. Long-term maintenance costs also differ. PEX has fewer corrosion-related repairs. Copper may require periodic fixes. Repairing copper is more labor-intensive. PEX repairs are often simpler. Insurance claims related to copper leaks are common. PEX reduces that risk. However, copper can last longer in ideal conditions. Long lifespan may offset initial cost. Budget considerations influence decisions heavily. Homeowners should consider total ownership cost. Not just installation price. PEX offers predictable performance. Copper offers traditional appeal. Both have financial trade-offs. Cost should align with long-term plans. Rental properties often favor PEX. Luxury homes may still choose copper. Context matters in cost decisions. There is no universal winner. Financial planning should be realistic. Comparing quotes helps clarify differences. Informed budgeting leads to satisfaction.

Resale Value and Buyer Perception

Buyers care about updated plumbing. They want reliability and low maintenance. Both PEX and copper are acceptable. Some buyers prefer copper due to familiarity. Others appreciate modern PEX systems. Inspection reports focus on condition, not material. A professionally installed repipe adds value. Leaking or outdated pipes reduce value. PEX does not lower resale value. In many markets, buyers expect it. Modern homes commonly use PEX. Transparency builds buyer confidence. Provide documentation of the repipe. Include permits and warranties. This reassures future owners. Material choice matters less than quality. Poor installation hurts value regardless of pipe type. Professional workmanship is key. Realtors focus on risk reduction. PEX’s resistance to leaks is attractive. Copper’s longevity appeals to traditional buyers. Regional preferences vary. Urban buyers often accept PEX easily. Rural buyers may prefer copper. Market trends favor modern systems. PEX is becoming standard. Resale value is not harmed by PEX. Proper installation protects investment. Future buyers want peace of mind. Quality plumbing supports strong resale outcomes.

Conclusion

Choosing between PEX and copper for a whole house repipe depends on practical factors. Both materials are proven and code-approved in the United States. PEX offers flexibility, lower labor costs, and corrosion resistance. Copper offers a long track record and traditional appeal. Climate, water quality, and home design all matter. Labor costs often tip the scale toward PEX. Freeze resistance makes PEX ideal in colder regions. Acidic water makes PEX a safer choice in many areas. Copper still performs well under stable conditions. Noise reduction and pressure balance favor PEX systems. Upfront cost savings are significant with PEX. Long-term maintenance is typically lower. Resale value is protected with either option. Professional installation matters more than material alone. Local codes should always be checked. Homeowners should consult licensed plumbers. There is no universal answer for every home. However, for many US households, PEX is the more practical choice. It balances performance, cost, and reliability effectively. A well-planned repipe with the right material ensures decades of confidence. You have not enough Humanizer words left. Upgrade your Surfer plan.